LoRaWAN Evaluation

Contents

Introduction

This project evaluates the LoRa frequency modulation and the LoRaWAN stack as an alternative for existing sensor setups using the technologies ZigBee and GSM. The current scope is to build a simple stack to collect sensor data end visualize them inside a web interface.

Within this work modular nodes were designed allowing to measure a variety of environmental metrics, including temperature, rain fall, humidity and sea level.

Software and hardware used on sensor nodes are documented to allow easy replication of the setup. Further multiple recommendations regarding software libraries and hardware are given.

All work happened in collaboration with the MESH LAB at Oahu, Hawaii, supervised by Dr. Brian Glazer and Dr. Edo Biagioni.

Note: This manual is work in progress and may receive updates over time. A list of changes will be attached to the bottom with corresponding dates.

Motivation

Based on the architecture of LoRaWAN, described in the TheThingsNetwork section, it allows a separation of sensor nodes and base stations. In simple terms this could be compared to a free cellular network where every user brings their own phone while the cellular base stations are managed by an organization with the public interest of connectivity. With LoRaWAN it is possible for researchers to deploy their sensor nodes while other entities, like universities or even states, handle the signal coverage.

The existing setup aimed to upgrade and extend uses both cellular GSM and ZigBee. While the formers base stations are managed by third parties it involves a recurring fee of usage, making large scale deployments less feasible. ZigBee requires researchers to manage their own gateways since there is no roaming standard or protocol for multiple users to share a base station.

LoRaWAN solves this by introducing a software stack which allows multiple entities to share base stations but also allows easy deployment of base stations contributing to the network as a whole.

Within this project existing sensor setups where rebuild to use LoRaWAN instead of GSM or ZigBee, reporting the same results while using a different medium of transportation. Collected data is stored in the same database as existing nodes, theoretically allowing a migration over time without changing work flows.

Aim

This work focuses unlike related scientific papers on a reproducible manual of said sensor setups. Multiple papers in the Related Work section prove the usability of LoRaWan as a concept and specifically for the Internet of Things and sensor network use case.

Specific steps to deploy a sensor network are described to combine available resources to a working, low-cost live monitoring system with possible data science pipelines.

Structure

Within this document no specifics of the LoRaWAN protocol are covered. For technical details on the LoRa frequency modulation or the LoRaWAN stack the Related Work section gives further information.

In the Hardware used microcontrollers and LoRaWAN gateways are covered. Additional documentation is provided on the custom designed Printed circuit board (PCB) as well as the used outdoor casing.

The Software section describes all code and tooling used and created within this project. Multiple sub-sections describe the full setup in detail and should be followed in that order.

Within the brief Resources section the advantages of the Cayenne Low Power Protocol for data transmission as well as an overview of used sensors for multiple environmental metrics.

Related Work

Using LoRaWAN for sensor networks is not a new idea and multiple papers describe a variety of experiments[1]. Also the technology of LoRa frequency modulation as well as the LoRaWAN stack was discussed in multiple publications[2].

This projects is similar to work of Davec et al[3] where they proof the feasibility of sensors over large distances gathering environmental metrics, in their case specifically temperature and soil moisture.

Next to academic publications this work is based on free documentation available online, notably the Arduino Reference and the many code examples by HelTec Inc. within their CubeCell repository.

Low-cost weather stations based on Arduino with custom circuit boards were also described by the OpenWeatherStation project and DFRobot, however neither uses LoRaWAN and is therefore more bound to local installations.

Complete setups from specialized vendors like Onset Computer Corporation offer professional weather stations, however come at a much higher price tag as solutions within this project.

Hardware

Within this section all hardware like microcontrollers, LoRaWAN base stations and outdoor casing are described.

Microcontroller

This section describes the used microcontrollers and development boards used within this setup. The microcontrollers is essentially an extremely small computer with hardware inputs and outputs. In simple terms, sensors are attached to the inputs and a LoRaWAN radio frequency module is connected to the outputs.

Using microcontrollers comes in two flavors, either as development boards with populated connectors, for instance a USB port and attached LEDs or as a plain module, which requires designing of a custom PCB. The former is used for rapid prototyping while the latter runs on an optimized PCB which only contains required functionality.

To simplify the development only microcontrollers compatible with the Arduino framework were considered. The framework abstracts talking to low level hardware components and offers a simple C API to control the microcontrollers behaviour. Additionally this allows to migrate code from one device to another with minimal code modifications sine both devices understand the same API.

Due to low price and using the LoRaWAN reference implementation the CubeCell

product line from the vendor Heltec Automation. Both development

boards CubeCell Dev-Board (htcc-ab01) and CubeCell Dev-Board Plus

(htcc-ab02) as well as the plain Module Plus (htcc-am02) were used.

Heltec CubeCell Dev-Board (Plus)

The development boards shown on the right both allow to connect sensors via GPIO Pins as well as I2C or serial console. Only the bigger Plus versions (bottom) contains two Analog to Digital converter (ADC) which are required for some sensor like the VH400 moisture sensor.

Additionally the Plus version comes with an attached LCD display which can be used for debugging or additional information during setup. No long time tests were performed to evaluate the UV resistance of the display.

For outdoor setups they come with a solar charge controller and battery connector which allows the usage without a constant power supply.

Both boards use the same microcontroller and can run the same code.

Flashing is trivial by using the USB connection and the Platformio framework.

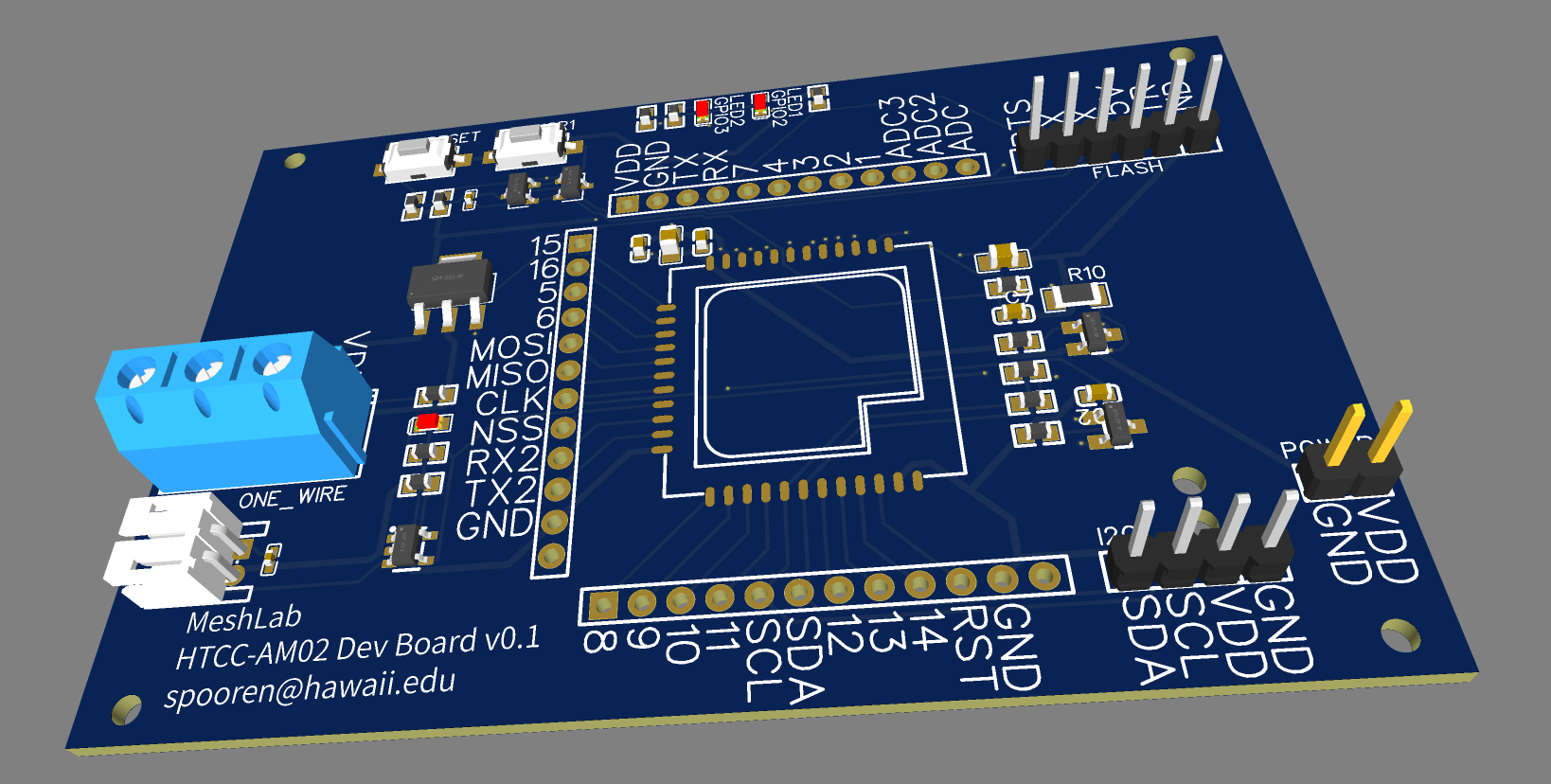

Heltec CubeCell Module Plus

The Module Plus allows (and requires) to use custom PCB and therefore only runs parts that are required. For production deployments the nodes would not need a LCD screen for debugging or a USB port for flashing. These components can simply be removed in the PCB design which reduces the number or parts, thereby cost and complexity.

Dev-Board Plus and Module Plus use the same microcontroller and therefore support the same connections.

More information on the PCB required for the Module Plus is available in the PCB section.

Gateways

While the Microcontrollers with an attached LoRaWAN radio frequency module mostly send data, the receiving part is called gateway. Essentially it is a device with a LoRaWAN compatible receiver attached as well as an Internet connection. Received packages are forwarded to a brooker. More details on that are available in the LoRaWAN section

Within this project the following three gateways were used as described below. This was partly necessary as LoRaWAN coverage with TheThingsNetwork broker were limited within the area of research, Honolulu, Ohau, Hawaii. At other locations institutions or private entities may already provide coverage free of charge. Using the TTNMapper it’s possible to see a local coverage map and determine if a self maintained gateway is required.

The Things Indoor Gateways

This gateway allows simple operation since it’s developed by the same people as the used LoRaWAN broker. It was used during local development and allows quick migration between different locations. While not waterproof, using additional casing and attaching an external antenna it can also be used as a outdoor gateway. For mobile development it is possible to power the gateway via a USB-C cable.

A complete install and maintenance guide is available in the vendors documentation and is not replicated here.

Heltec HT-M00

Just as the microcontrollers Heltec offers a development gateway as well. At the time of writing this is the cheapest development gateway available with a price of about $40. The upstream documentation guides through the installation process of the gateway into TheThingsNetwork broker. For mobile development it is possible to power the gateway via a USB-C cable.

Mikrotik wAP LR9 kit

Lastly the outdoor LoRaWAN gateway from the vendor Mikrotik (in 900MHz or 860MHz) offers the, at the time of writing, cheapest outdoor gateway. With Power over Ethernet (PoE) the installation is possible with a single Ethernet cable without requiring (ideally elevated) deployment location.

Printed Circuit Board

This section briefly describes the PCBs designed within this project. While breadboards are often used for prototyping with microcontroller, real deployments should use custom PCBs since they offer a more reliable setup.

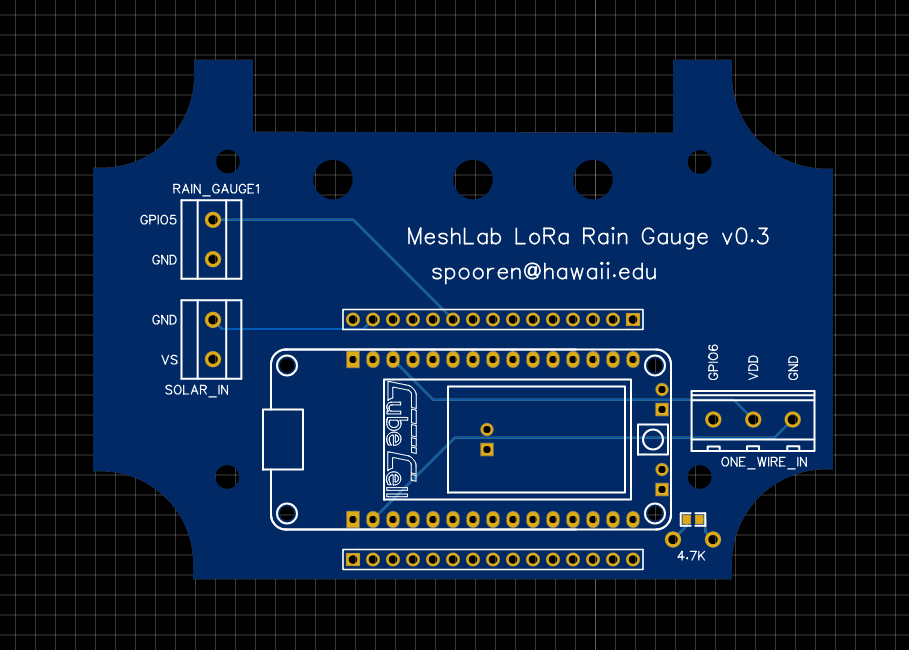

The project scope required a rain gauge sensor as well as a temperature sensor to transmit measurements over LoRaWAN to a online database. With the below described PCB it is possible to attach a Heltec HTCC-AB02 as well as the two sensors within minutes.

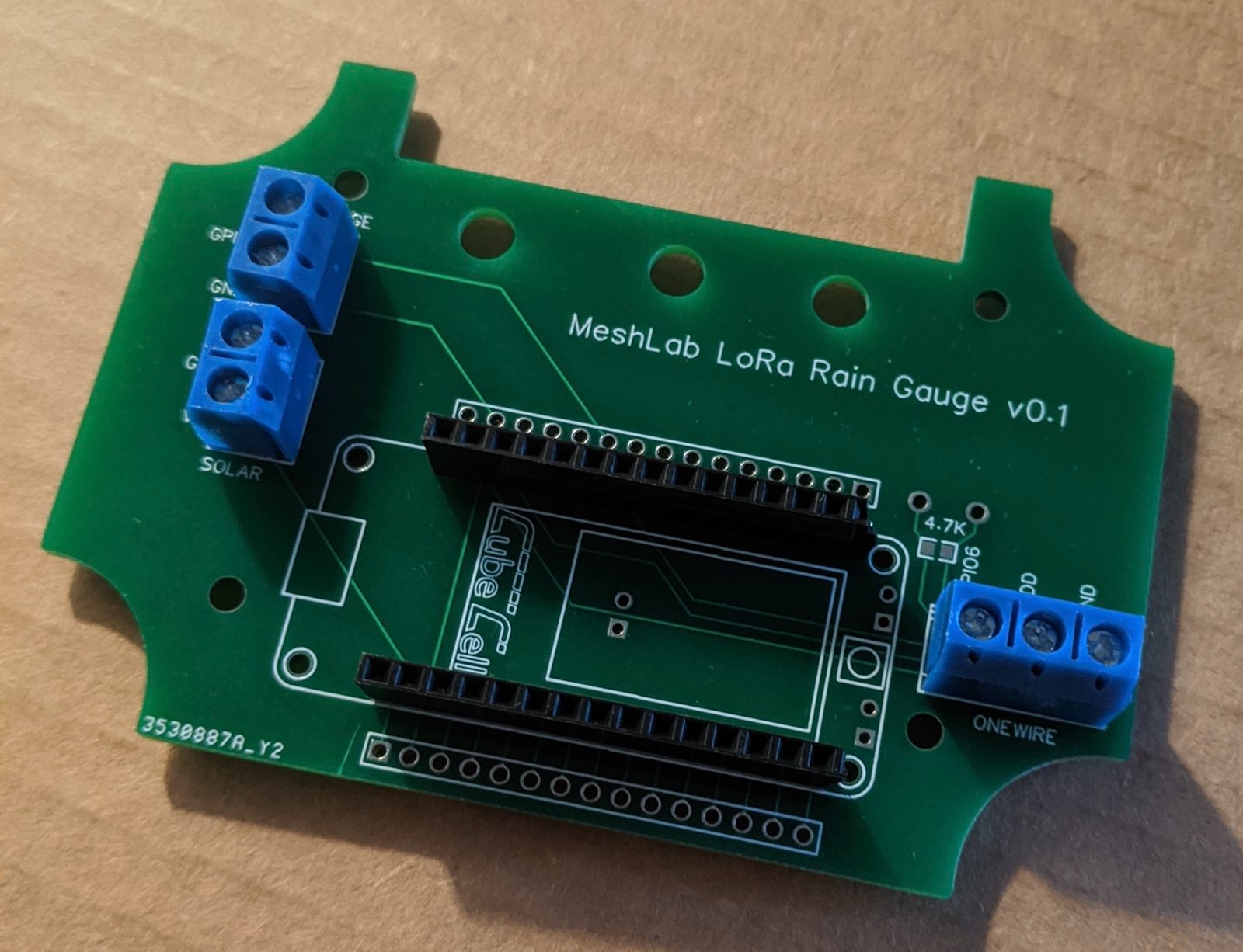

Rain Gauge PCB

As mentioned above the two values temperature and rain fall were to be

collected and send to an online database. First prototypes using a breadboard

and a Heltec HTCC-AB02 worked out as expected, so the same exact circuit was

transfered in a PCB. On the right side a picture of the PCB is shown. The labels

RAIN_GAUGE, SOLAR_IN and ONE_WIRE_IN contain screw terminals which allow

easy attaching of the sensor cables.

Below is a printed and mostly assembled (missing 4.7k resistor) board. The CubeCell board can be directly attached to the pin headers, the labeled screw terminals allow a simple connection of sensors. Next to the attached pin headers is a second row of pins which can be used for developing to connect any other GPIO which might be of interest in the future.

An EasyEda project file is available here for customization or ordering online.

Additionally the BOM, Gerber and Pick & Place files are available:

- BOM_PCB_rain-box_htcc-ab02.csv

- Gerber_PCB_rain-box_htcc-ab02.zip

- PickAndPlace_PCB_rain-box_htcc-ab02.csv

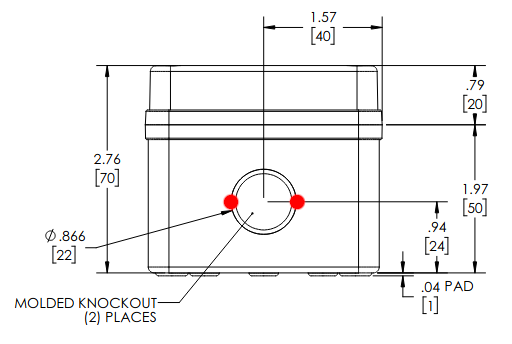

The PCB has a custom cutting so it fits perfectly into the outdoor case

PTK-18420-C by Bud Industries, Inc.. It is important to order the C

version since a clear cover is required to allow solar charging. Using cable

glands it’s possible to connect external sensors. The picture below shows two

possible positions for 7mm holes to attach PG7 cable glands. Silicon was

added around the cable glands for better long term water resistance.

The full box specifications are available on the vendors website or as an attached resource.

It is possible to use the Pick and Place file to

order all parts soldered on or solder all components manually. In that case a

4.7K resistor should be added on the bottom left instead of a flat resistor.

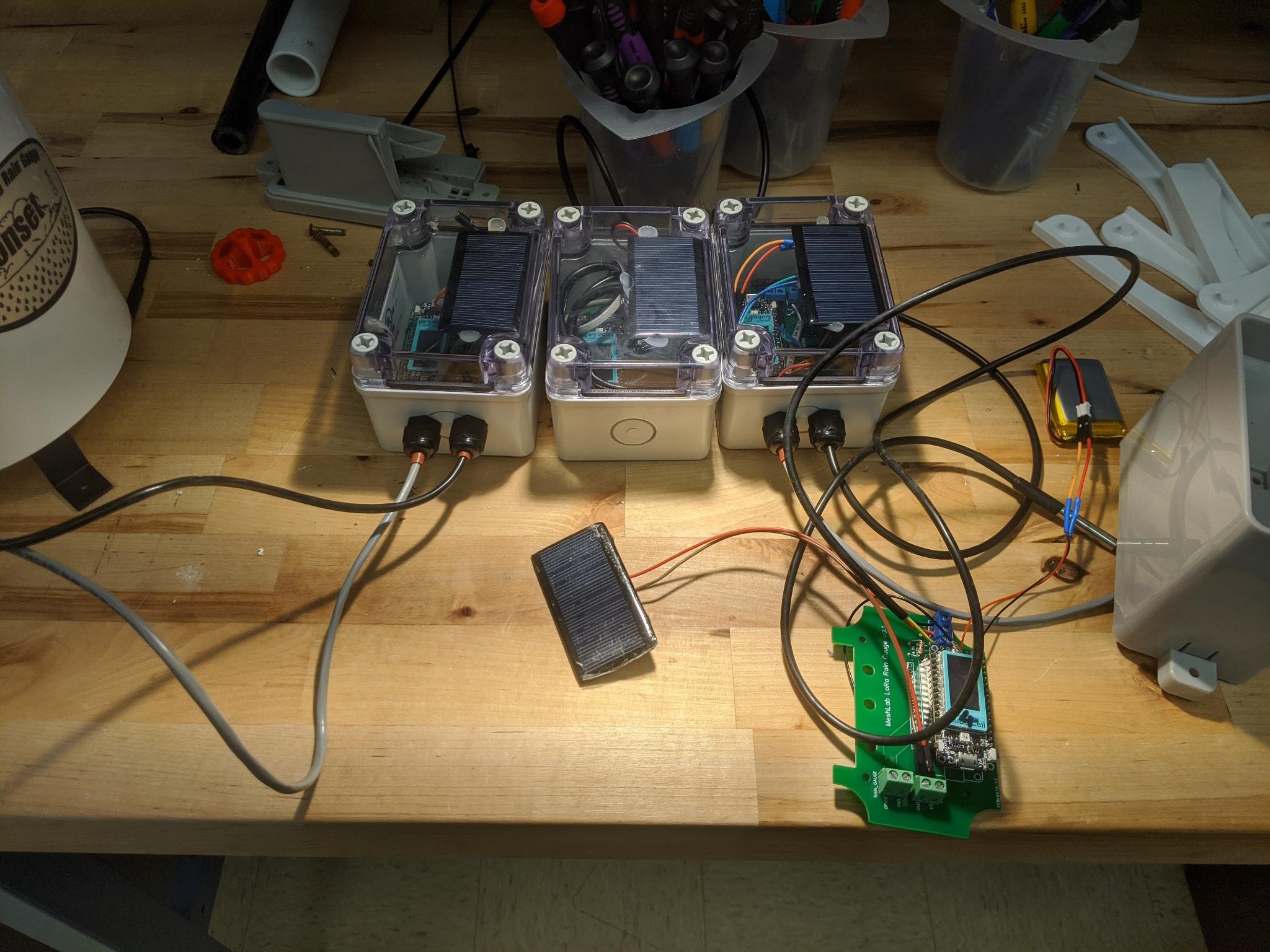

A picture of an assembled Rain Box is shown below. The picture shows four different setups of the rain gauges.

- The left box has a HOBO RG3 rain gauge

- The middle box has only a DS18B20 temperature sensor is connected inside the box. This was done to measure the maximum daily temperature inside the box.

- The right box has both a temperature sensor and a MISOL rain guage attached. By the time of writing (2021-09-16) the official vendor website is unreachable.

- In front is a PCB board without a box showing a connected Heltec HTCC-AB02.

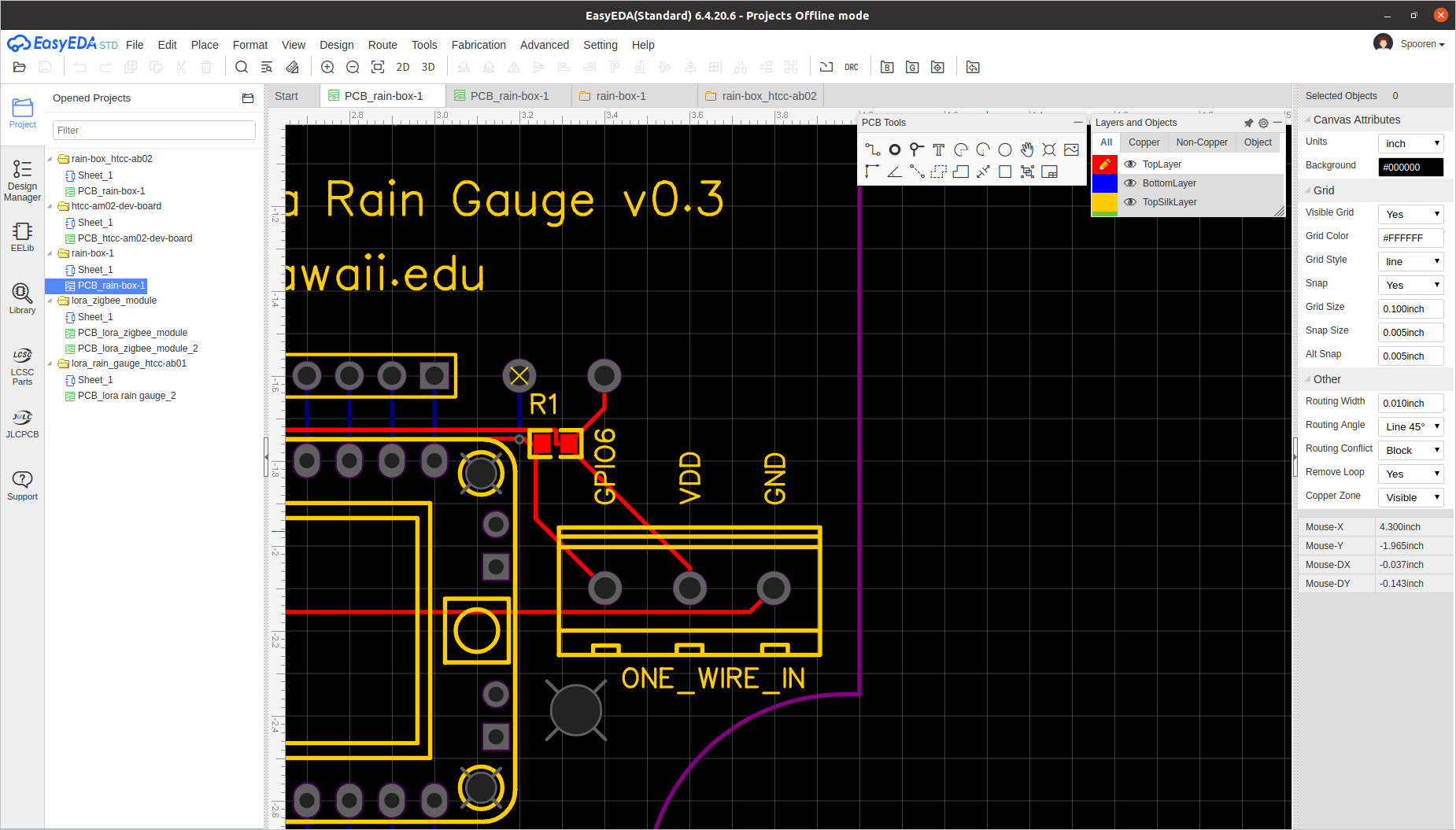

PCB Editor

To design PCBs a variety of tools is available for free. However the number of tools that are available on the three main platforms Windows, MacOSX and Linux is limited. Within this project EasyEda was used for it’s simple usage and integration with part libraries, which would simplify the ordering process.

EasyEda comes with a tight integration of the PCB vendor JLCPCB which offers both creation of PCBs and also soldering of selected components.

An extensive official documentation is available in English on the vendors website include video tutorials.

If EasyEda is not an option the open source tools LibrePCB or KiCad could be used instead, however they are not covered here.

Software

This section describes all code and tooling used and created within this project. It is recommended to read the Hardware section first to have the required sensor nodes.

TheThingsNetwork

This section gives a brief introduction to the free TheThingsNetwork service which provides a Network server to handle LoRaWAN authentication, forwarding and data access. More information on the LoRaWAN stack Rizzi et al[2] give a great introduction how communication from sensor node to user facing Application server works.

In short, TheThingsNetwork is a free, partly commercial, partly community driven service which handles the management of nodes, keys, base stations and APIs to access collected data. The picture below show a simplified overview of the stack.

Sensor Nodes collect data and send it via LoRa radio frequency modulation (red lines) to Gateways. A gateway has a LoRa compatible radio module and antenna attach and listens for incoming messages. Once received, messages are forwarded to a broker or Network Server. The network server, in this setups case thethingsnetwork.org, manages user accounts and applications. Each application has multiple Nodes assigned with individual login credentials. Forwarded messages from gateways are offered via MQTT to user of specified application. User controlled Application Servers can listen to MQTT streams and store sensor data for further processing.

No user can access applications of other users and all traffic, starting from sensor nodes until the application server is encrypted. This allows a federation of infrastructure since multiple entities can share access to a single gateway without being able to manipulate each others data.

As an outcome, both private hobbyists and institutions like universities can offer gateway access and thereby work together to cover large areas. Different projects don’t have to manage their infrastructure independently but can share gateways. Since all traffic is encrypted and authenticated as defined by the LoRaWAN standard, no code has to be written by users to allow secure connections.

Lastly multiple integrations allow even easier setups than described within this document. Instead of running a self managed database, it is also possible to rely on cloud services storing MQTT messages and offering convenient interfaces.

Web interface (Console)

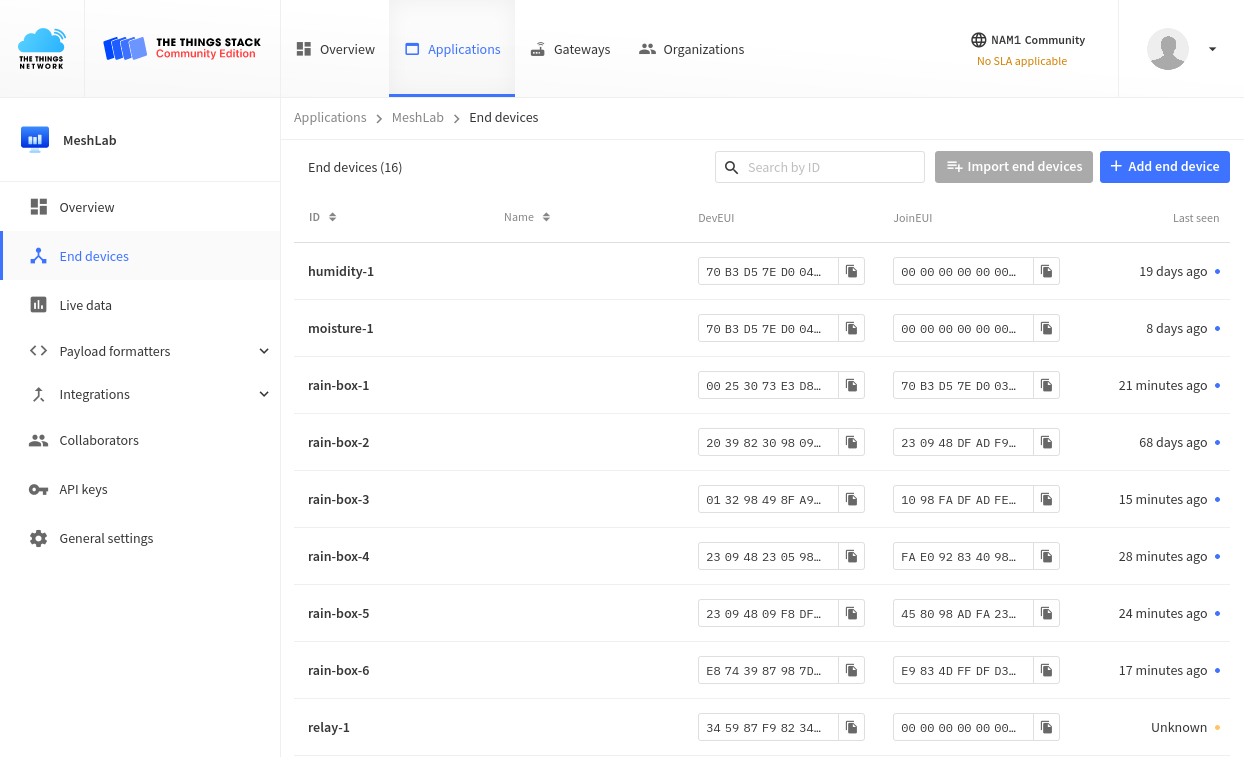

The cloud service requires a free online account and the setup of an Application. Each application then contains multiple End devices which which provide sensor data. Received data is offered via an MQTT API can should be consumed by a user controlled database, in this setup InfluxDB or one of the integrations.

Within this project the North American Cloud (nam1) was used, other locations should use Europe 1 (eu1) or Australia 1 (au1). While the outdated v2 stack is still offered, it should not be used due to it’s upcoming end of life (December 2021). Many resources online still document the v2 which should be avoided.

The above image shows currently active end devices, their identifiers as well as the time of the last received message.

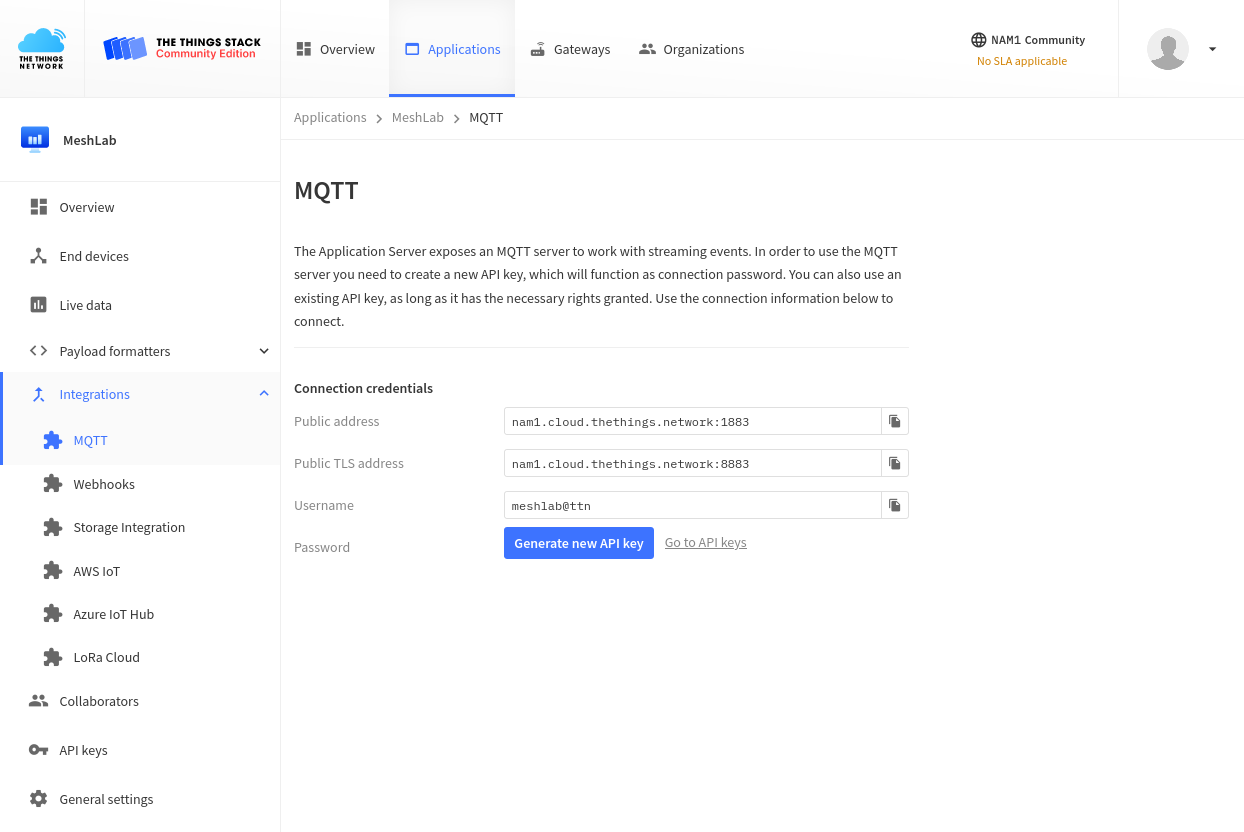

Aboves picture shows the MQTT login credentials which can be either used within the InfluxDB setup to have Telegraf listen to MQTT and store data or for other applications.

In the code appendix is a short Python script called

mqtt2json.py which listens to the MQTT stream and outputs

lines of JSON which can be consumed by other applications. A generic script

like this allows custom downstream handling of incoming sensor data. As proof of

concept the script below is parsed by another tool adding measurements to a SQL

database and visualize them via a custom web pagegrogdata. Nodes are

identified via the from field and all payload is stored in the p field,

containing data fields based on CayenneLPP.

Below is an example output of the script which could be read by future tooling using the JSON Lines standard

{"from": "rain-box-5", "p": {"temperature_1": 23.1}}

{"from": "rain-box-1", "p": {"temperature_1": 23.5}}

{"from": "sonic-2", "p": {"distance_1": 4.991}}

{"from": "rain-box-6", "p": {"temperature_1": 21.4}}

{"from": "rain-box-4", "p": {"digital_out_1": 2, "voltage_1": 4.15}}

{"from": "sonic-2", "p": {"distance_1": 5}}

{"from": "rain-box-5", "p": {"digital_out_1": 2, "voltage_1": 4.22}}

{"from": "sonic-2", "p": {"distance_1": 5}}

{"from": "rain-box-4", "p": {"temperature_1": 24.7}}

{"from": "rain-box-5", "p": {"temperature_1": 23.6}}

{"from": "rain-box-1", "p": {"temperature_1": 23.6}}

{"from": "sonic-2", "p": {"distance_1": 5}}

{"from": "rain-box-6", "p": {"temperature_1": 21.5}}

{"from": "rain-box-3", "p": {"temperature_1": 24.1}}

{"from": "sonic-2", "p": {"distance_1": 5}}

{"from": "sonic-2", "p": {"distance_1": 5}}

{"from": "rain-box-4", "p": {"temperature_1": 24.6}}

{"from": "rain-box-5", "p": {"temperature_1": 23}}

{"from": "rain-box-1", "p": {"temperature_1": 23.7}}

...

Platformio

This section describes the usage of the Platformio framework for embedded development. Similar to the Arduino IDE it allows the management of dependencies and compilation for a wide variety of devices.

Due to its simple installation and full support for the used hardware it was preferred over other the Arduino IDE, however other tooling should be possible as well.

Installation

A full installation guide is available in the upstream documentation

however the basic installation boils down to a running Python 3 installation

combined with the Python Packet Manager or curl:

pip install -U platformio

# or

python3 -c "$(curl -fsSL https://raw.githubusercontent.com/platformio/platformio/master/scripts/get-platformio.py)"

After the installation the shortcut pio executes the binary.

Creating a project

Adding projects is as easy as creating a folder and running pio to initialize

the project in the current folder.

mkdir project/ && cd project/

pio project init

After the initialization the following files are created:

include/ # header files

lib/ # libraries

platformio.ini # platformio configuration file

src/ # source code (e.g. main.cpp)

test/ # automatic tests

See the Git repository folder node/ to see the main project structure.

platformio.ini

The configuration file contains one or multiple environments per used device

type. Within this projects environments for the devices cube_cell_board,

cubecell_board_plus and cubecell_module_plus are used. The file below shows

one of the three environments and defines multiple aspects or the project which

simplify development:

board_build.ardiono.*defines values passed during compile time to enable and configure specific features.upload_portdefines the local connection, which allows to have multiple devices connected at once and test them in parallellib_depsdefines all required dependencies which can be hosted within the Platformio registry or Git repositories directly.

[env:cubecell_board_plus]

board = cubecell_board_plus

platform = asrmicro650x

framework = arduino

board_build.arduino.lorawan.region = US915

board_build.arduino.lorawan.netmode = OTAA

board_build.arduino.lorawan.adr = ON

monitor_speed = 115200

upload_port = /dev/ttyUSB0

lib_deps =

https://github.com/ElectronicCats/CayenneLPP.git#master

bblanchon/ArduinoJson @ ^6.17.2

practicalarduino/SHT1x@0.0.0-alpha+sha.be7042c3e3

Flashing nodes

Once a sensor node is connected it’s can be flashed using the following command:

pio run --target upload

For convenience it is also possible to upload and monitor the serial output at once:

pio run --target upload --target monitor

Sensor Node

This section describes the software used on sensor nodes. All code is deployed

on devices as described in the Platformio section. After flashing

nodes are provisioned using the provision_node.py script

in combination with YAML files containing the per device specific information.

The detail section below contain the following content:

- config.h Contains node specific configuration options, like the

sensors to enable on which PINs. This should be modified per use case, for

instance when creating a new series of rain gauges measuring moisture as well,

the sensor should be enabled here. Per node configuration happens via the

provision_node.pyscript after flashing. - main.cpp Contains the main loop which connects to sensors and sends LoRaWAN packets.

- VH400.cpp Minimal library to communicate with VH400 moisture sensor.

- MB7389.cpp Minimal library to communicate with MB7389 ultrasonic sensor.

Using provision_node.py for AT_Commands

The Heltec Dev Boards allow the configuration of certain on-device variables

via AT_Commands. Those commands can be communicated via a serial connection

(e.g. over USB) and modify per-device specific LoRaWAN credentials or user

defined values.

A list of the most important AT_Commands is shown below:

| AT Command | Value |

|---|---|

| +LORAWAN=1 | LoRaWAN 1, LoRa 0 |

| +OTAA=1 | OTAA -1, ABP-0 |

| +Class=A | Class A or C |

| +ADR=1 | 1 on 0 for off |

| +IsTxConfirmed=1 | LoRaWAN ACK Message 1 on, 0 off. |

| +AppPort=2 | The Application Port 2 for general APPs and 10 for TTN MAPPER. |

| +DutyCycle=60000 | The time between transmission in mS. Typically, 15000 to 3600000 |

| +DevEui=??? | Unique (OTAA Mode) |

| +AppEui=??? | Unique (OTAA Mode) |

| +AppKey=??? | Unique (OTAA Mode) |

| +ChipID=? | get ChipID |

| +JOIN=1 | start join |

To allow managing multiple devices YAML configuration files are used containing credentials of nodes. After flashing a node via Platformio a node can be configured by running a command like the folloing:

python provision_node.py rain-box-1

Below is an illustrative content of ./nodes/rain-box-1.yml. All contents of

the at_commands dictionary are executed via the provision script. All other

values like case and sensors can be used to keep an inventory in a

machine-readable format.

The special value mmPerTip is a user AT_Commands which is defined within

main.cpp and determines how many millimeters a rain gauge tip adds to the

total value.

case:

type: PTK-18420-C

label: rain-box-1

sensors:

- HOBO RG-3

at_commands:

DevEui: 0025307XXXXXXXXX

AppEui: 70B3D57ED003A1D1

AppEui: 70B3D57XXXXXXXXX

AppKey: 1F41DD0XXXXXXXXXXXXXXXXXXXXXXXXX

mmPerTip: 0.3851

InfluxDB Database

This sections covers briefly the setup of InfluxDB, a time series database which allows storing and querying metrics. Just like all other tools used within this document it’s open source and all code is available online.

Using InfluxDB comes with the two advantages of offering integrations for both Grafana as well consuming MQTT events, which is the way the LoRaWAN brooker reports metrics.

Installation of InfluxDB

While InfluxDB 2.0 was released this year, this document describes the setup and usage of InfluxDB 1.8. All tooling should be compatible with both versions and a migration guide might be added later on.

The upstream documentation explains the installation process for various setups,

for the RaspberryPi setup the Ubuntu & Debian steps should

be followed. Within this documentation both database and user are called

telegraf, however other use cases may use other values.

Installation of Telegraf

Telegraf is used to consume MQTT events and store them inside InfluxDB.

InfluxDB and Telegraf are both developed by InfluxData Inc., so a similar installation process is offered. Again the official installation guide for Ubuntu & Debian should be used.

Once installed a custom configuration is required to consume data from

TheThingsNetwork and store them locally. All values in <...> should be changed

accordingly to the actual setup.

# /etc/telegraf/telegraf.conf

[global_tags]

[agent]

interval = "10s"

round_interval = true

metric_batch_size = 1000

metric_buffer_limit = 10000

collection_jitter = "0s"

flush_interval = "10s"

flush_jitter = "0s"

precision = ""

hostname = ""

omit_hostname = false

[[outputs.influxdb]]

database = "telegraf"

urls = [ "http://localhost:8086" ]

username = "<influxdb_username>"

password = "<influxdb_password>"

[[inputs.mqtt_consumer]]

servers = ["tcp://nam1.cloud.thethings.network:1883"]

topics = [ "#" ]

username = "<thethingsnetwork_username>"

password = "NNSXS.<thethingsnetwork_api_token>"

data_format = "json"

tag_keys = [

"end_device_ids_device_id"

]

Once both services are running one should proceed setting up Grafana to create a dashboard presenting collected metrics.

Grafana Dashboard

Presenting collected data is important to make them accessible and give an overview of events before starting in-depths analytics. While multiple approaches to visualize data exists, this section describes the setup of Grafana.

The advantages of Grafana compared to other solutions is the fact that without any coding skills appealing graphs and gauges can be created, offering a live and interactive user interface.

Within this setup the combination with the InfluxDB database is described, however it is possible to visualize other data sources via Grafana.

Installation

To allow a cheap and reproducible setup these steps are done on a RaspberryPi running Raspbian, which allows low cost data hosing without requiring any server setups. However it is equally possible to run this on a virtual machine or even a laptop for testing.

The Raspbian ports of Grafana are outdated and therefore the official Grafana repository is used instead:

echo "deb https://packages.grafana.com/oss/deb stable main" | \docs

sudo tee -a /etc/apt/sources.list.d/grafana.list

wget -q -O - https://packages.grafana.com/gpg.key | sudo apt-key add -

sudo apt update

sudo apt install -y grafana-rpi

More details on the Grafana installation steps are available in the official documentation.

Adding InfluxDB as data source

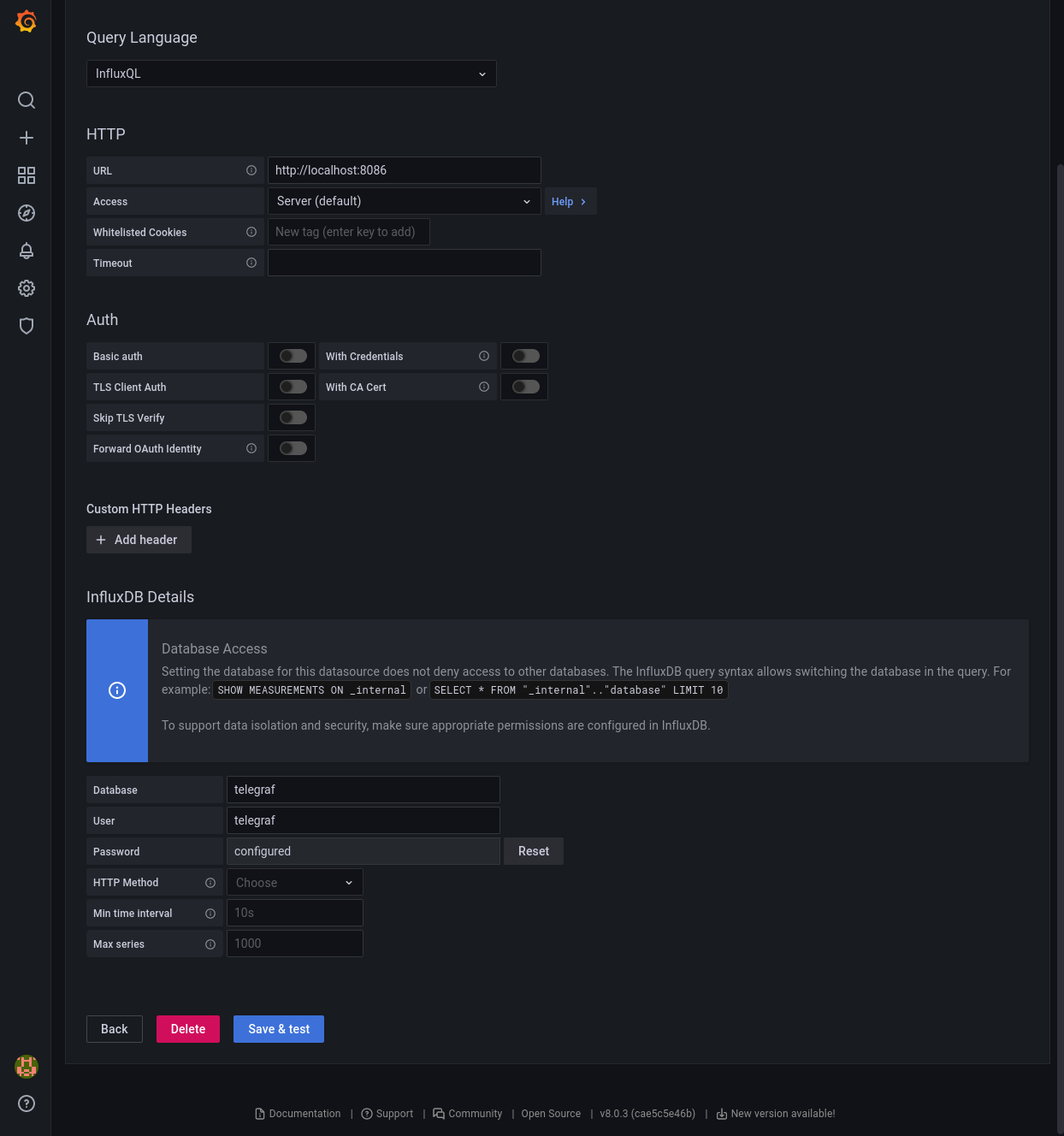

This setup run both Grafana as well as InfluxDB on a single RaspberryPi. Therefore it’s possible to access the data locally. Other setups may use remote database on distributed systems, where data is stored on different machines than visualized.

InfluxDB runs per default on port 8086 and if running, is available on

localhost. None of the extra options need to be activated since a local setup

doesn’t require extra authentication settings except the login credentials set

in the InfluxDB database setup.

Configure a graphs

A generic manual to add graphs or panels is provided by the Grafana Project itself within their documentation.

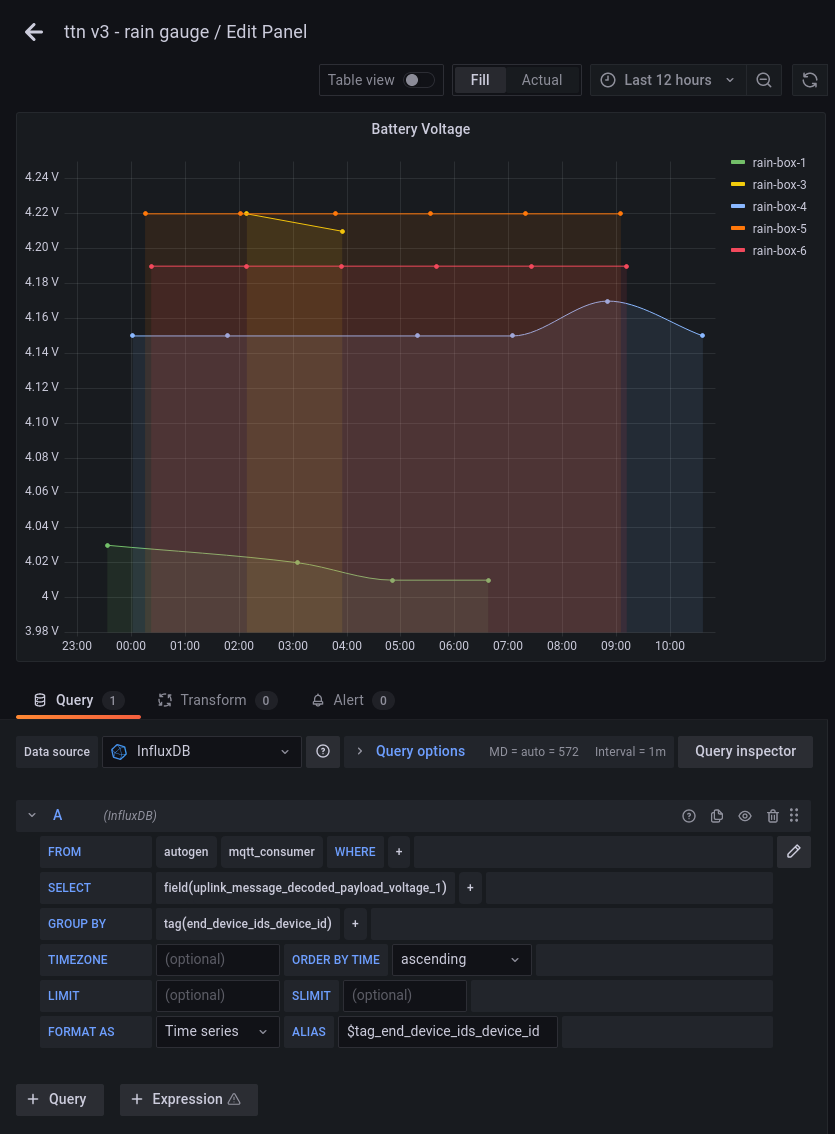

This example describes how to get the battery voltage of all available nodes.

A running InfluxDB receives data via Telegraf, feeding a MQTT stream into the

time series database. If using the same options as in the InfluxDB section,

Grafana will present a mqtt_consumer table from which data can be selected.

Since the CayenneLPP protocol is used to encode senor data for LoRaWAN transmission, all fields in the table follow a specific schema:

uplink_message_decoded_payload_<cayennelpp_type>_<cayennelpp_id>

All metrics start with uplink_message_decoded_payload since that contains

transmissions from the node. Other fields may contain IDs of used gateways or

transmission quality (uplink_message_rx_metadata_0_rssi), however these are

more relevant to monitor the nodes health.

The field of our interest is voltage with the ID 1, the field is therefore

called as follows:

uplink_message_decoded_payload_voltage_1

Once the field is selected measurements should be grouped by the device IDs.

Grouping by means that a graph is created per device instead of showing all data

in a single graph. The tag for grouping is called end_device_ids_device_id.

Lastly to improve readability it is possible to assign an alias to each graph.

Instead of having the lengthy full description of a measurement (see below) only

the device identifier can be shown. To do so the special value

$tag_end_device_ids_device_id is added to the alias field.

mqtt_consumer.uplink_message_decoded_payload_voltage_1 {end_device_ids_device_id: rain-box-6}

Example Dashboard

Below is a screenshot of a demo setup which includes two graphs of measured metrics (rain fall and temperature) and below an overview of the nodes over the last week. It is possible to interactively select smaller and bigger time frames and see precise values for specific times and dates.

Aboves two graphs show rain events that happened at different location in Honolulu, Hawaii. It’s possible to zoom into specific time ranges to see the total amount of rain for that day, hour or minute.

The temperature graph below the rain fall shows a repeating pattern of

temperature changes. Two special cases are handled in this graph showing where

rain-box-1 shows the inner enclosing temperature and rain-box-6 is

stationed in a cooled lab, therefore the constantly low temperature.

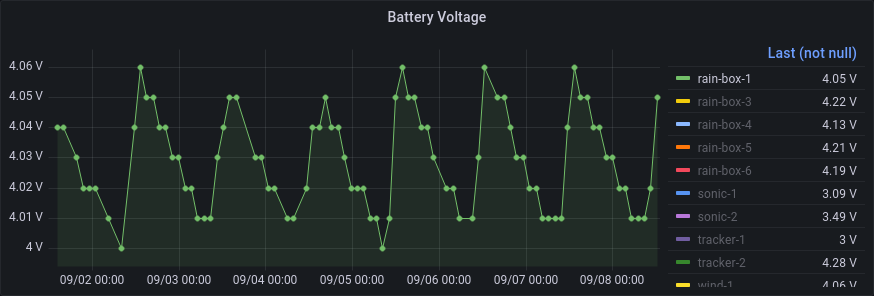

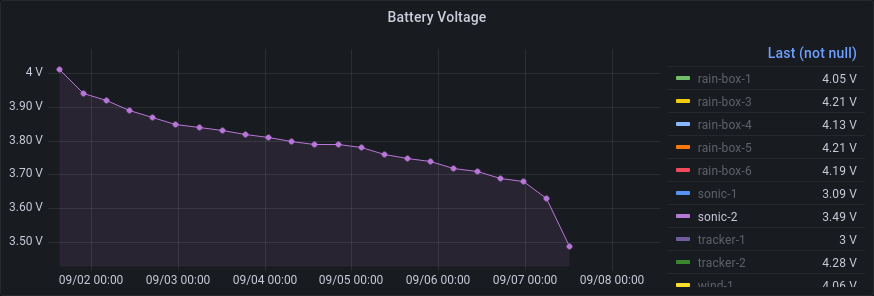

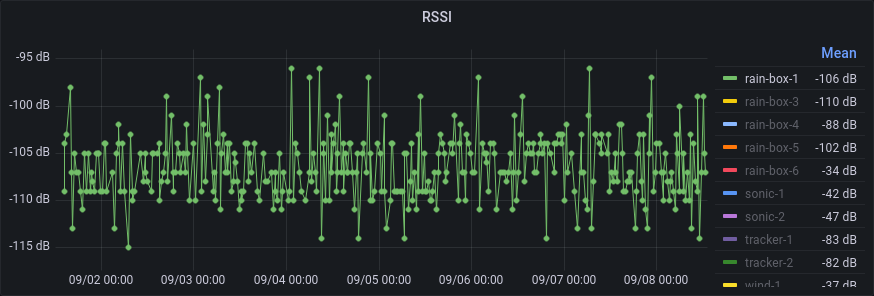

Additional values can be measured to track the health of sensors, most importantly the battery voltages and connection quality (RSSI).

The graph above shows how the battery voltage is dropping every night but recharged on sunrise.

On the contrary, above graphs show that the node sonic-2 doesn’t recharge via

it’s attached solar panel and therefore shuts off once the battery voltage is to

low for further LoRa transmissions. The node need manual inspection and

probably a solar panel replacement.

The graph above shows shows the varying values of RSSI, which describes the

connection quality. For LoRa values down to -120dB are fine for a stable

connection, so the node rain-box-1 should have a stable connection.

Resources

CayenneLPP

This section explain CayenneLPP (Low Power Protocol) which is used to encode data on sensor nodes into a size efficient format and decode it in the backend back for further processing.

Cayenne is a platform developed by myDevices Inc. offering custom dashboards for device monitoring, alerts and more. They developed CayenneLPP and multiple open source implementation (C, Python of that protocol exists. The protocol allows a compromise between self describing data packets and size efficiency, which will be explained in the next section.

This sections below show three ways to encode node data to a binary format for sending over LoRa, a custom raw format, JSON and CayenneLPP. The example data is a temperature value of 18.6 degree Celsius, a battery voltage of 3.9V and a distance value of 43mm.

Encoding using raw Bits

The smaller a LoRaWAN packet is the less power is required to send it and the more airtime is available for other sensors. A simple solution would be just store all sensor data as binary fields one after another. The packet could have the following format:

<temperature><voltage><distance>

Representing floats in binary isn’t trivial to instead a prevision can be defined. For temperature two float digits are enough, for battery voltage a single float digit is fine and dinstance is always a integer.

This means values can be multiple by 100 respectively 10. The temperature value

becomes 1860 and the voltage becomes 39. Both considering that measured

temperature will never be above 99.99 degree Celsius and batter voltage should

exceed 9.9V (4.2V really). For distance a maximum of 5000mm should be used.

To calculate the maximum bits needed data, the maximum values are converted to binary format the bit counted, easily possible with some Python:

>>> format(9999, "b") # max value

'10011100001111'

>>> len(format(9999, "b"))

14

>>> format(99, "b") # max value

'1100011'

>>> len(format(99, "b"))

7

>>> format(5000, "b") # max value

'1001110001000'

>>> len(format(5000, "b"))

13

>>>

Above calculation shows that 14 Bits are needed for temperature, 7 for battery voltage and 13 for distance. Now the custom data format becomes more specific as shown below:

| temperature 14 | volt 7 | distance 13 |

| xxxxxxxxxxxxxx | xxxxxxx | xxxxxxxxxxxxx |

Below we calculate the specific values and pad them with zeros.

>>> format(1860, "b")

'11101000100'

>>> format(39, "b")

'100111'

>>> format(43, "b")

'101011'

The resulting packet would look like this with a total size of 34 Bits.

| temperature 14 | volt 7 | distance 13 |

| 00011101000100 | 0101011 | 0000000101011 |

The receiving backend could decode this data by reading the first 14 Bits as integer and dividing the value by 100 to calculate the temperature, followed by reading Bit 15 until 21 as integer and dividing it by 10 to calculate the battery voltage. The remaining 13 Bit can be directly read as distance.

While this approach works and data is efficiently exchanged between sensor node and backend, the calculation is not trivial to understand. More problematic is the extendability of this approach: Newly added sensors may use a different set of sensors and therefore require data fields. As the exchanged data is just Bits, it’s not possible to know what the data contains. In other words, the format is extremely static and ideally the data would be more self explaining so a backend would know what value it is decoding.

Encoding using JSON

The JSON format is extremely popular in web application to exchange all kinds of data. It is human readable, supports all our data types directly (float and integer) and allows to verbosely describe data fields. The example data could be decoded as below:

{

"temperature_1": 18.6,

"voltage_1": 3.9,

"distance_1": 43

}

As printed above, the format would take a total of 73 Bytes (584 Bits) which is nearly 20 times bigger than using the raw format. Even a slightly optimized version as shown below would still require 28 Bytes (224 Bits) meaning 7 times bigger.

{"t1":18.6,"v1":3.9,"d1":43}

Encoding using CayenneLPP

CayenneLPP uses a compromise of both approaches, the data is very compact while being self descriptive. To archive that common measurement types are available with a 1 Byte data type descriptor and a 1 Byte data type channel (or ID). Each data type, be it temperature, GPS or relative humidity is described by a number between 0 and 255, a official reference implementation is available in the Cayenne Docs. Since all data types are based on IPSO data types other implementations support additional values, like voltage, altitude and distance.

Adding those values on device is done by a creating a CayenneLPP frame and

adding values. More details are available in main.cpp

implementation, however below is an simplified example.

CayenneLPP lpp(LORAWAN_APP_DATA_MAX_SIZE); // create frame

lpp.addVoltage(1, getBatteryVoltage()); // add voltage

lpp.addDistance(1, distance); // add distance in mm

lpp.addTemperature(1, temperature); // add temperature in Celsius

appDataSize = lpp.getSize(); // calculate size

memcpy(appData, lpp.getBuffer(), appDataSize); // copy Bytes to LoRaWAN packet

The same is possible to do via Python using the pycayennelpp package:

from cayennelpp import LppFrame

frame = LppFrame()

frame.add_temperature(0, 18.6)

frame.add_distance(1, 43)

frame.add_voltage(1, 3.9)

buffer = bytes(frame)

print(len(buffer))

The result are 14 Bytes and thereby half the size of using JSON. For

measurements which are not directly supported by the implementations, like

number of satelites for GPS measurements, it is possible to use the commands

addDigitalInput or addDigitalOutput (unsigned 32 Bit Integer) and

addAnalogInput or addAnalogOutput (float with 3 decimals).

Decoding in Backend

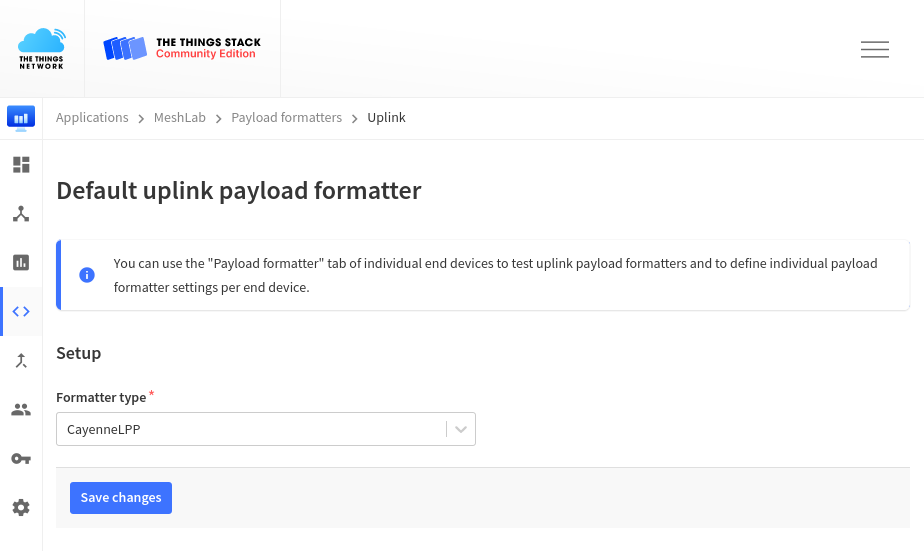

The receiving backend allows to decode incoming data before offering it via MQTT. This is very useful so different applications listening to the MQTT stream can directly process the decoded payload rather than implementing that per client, allowing as well to upgrade the communication used for nodes without modifying clients.

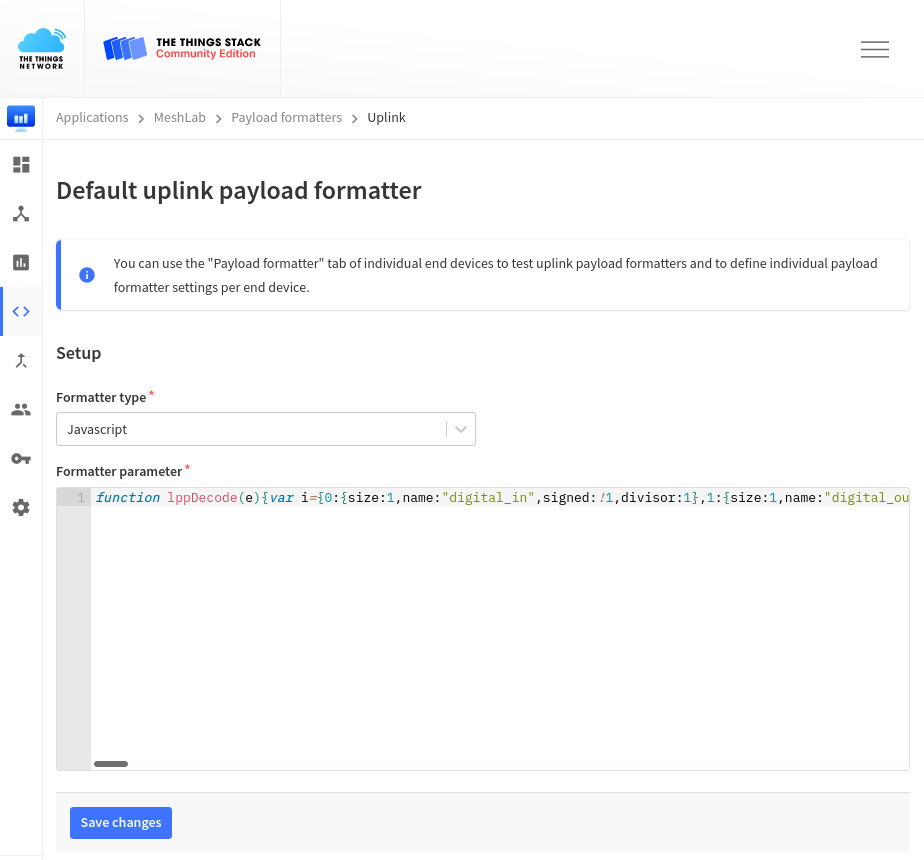

TheThingsNetwork offers to automatically decode CayenneLPP frames using the Payload Formatter menu entry.

However, since TheThingsNetwork uses the reference implementation of MyDevices

they don’t support decoding some additional data types, like distance. If these

measurements are used it is possible to use a custom JavaScript decoder as

offered by ElectronicCats to be used directly in TheThingsNetwork. The

decoder.min.js can be pasted into the text field of the Payload

Formatter menu entry:

The

mindecoder version is required as TheThingsNetwork limits the total size of decoding scripts and the formated version exceeds that limit.

Used payload types

Within this project the following payload types and IDs are used.

| JSON value | description |

|---|---|

analog_in_1 | rain mm/m |

analog_in_2 | soil moisture |

digital_out_1 | running software version (integer) |

temperature_1 | temperature |

voltage_1 | battery voltage |

distance_1 | distance to sea level |

Sensors

This section describes briefly sensors used within this project. All of them are supported by the Arduino framework an can be connected in any variation to the described microcontrollers.

Distance

To measure the distance between a fixed point and sea level the ultrasonic

MB7389 sensor from MaxBotix Inc. was used. It offers a distance range of

300mm to 5000mm (5m). Measurements happen 6 times per second and are

readable via an analog, pulse width or serial output. The easiest implementation

is done by using Arduinos softwareserial and read the

distance values as chars. A full data sheet is available on the vendors

website.

Rain fall

For rain fall two different rain gauges are used. While one is the de-facto

standard for scientific publications, the other allows measurements at a much

lower price. Both are usable by using a simple tip counter via an GPIO

interrupt and are simply connected to a GND PIN and whichever PIN was

configured with the interrupt.

ONSET HOBO RG-3

The HOBO Rain Gauge by Onset Computer Corporation offers a high quality metal casing and is described as the default rain gauge for scientific publications. With it’s precision comes the price of around $400 which may exceed the budget for some use cases.

One tip means

0.254mmor0.1"of rainfall.

Misol WH-SP-RG

An alternative to is the WH-SP-RG by Misol. At the time of writing (2021-09-21) the vendors website is not reachable, however other websites sell the rain gauge for around $20.

One tip means

0.3851mmof rainfall.

Soil Moisture

For soil moisture the VH400 by Vegetronix, Inc is supported. The sensor is

connected to an ADC (Analog Digital Converter) PIN and the measured

resistance describes the volumetric water content by using a piecewise

curve provided by the vendor. The curve is implemented in the provided

mini library. The sensor costs around $40.

Temperature

For waterproof temperature measuring a DS18B20 sold by Adafruit Industries, LLC is used. Adafruit ships their own libraries so minimal integration needs to be coded. The sensor uses three wires which can be directly connected to the custom PCB. The sensor costs ardoung $10 on the Adafruit website.

Conclusion

This project started initially with the evaluation of pure LoRa frequency

modulation using the Arduino library arduino-LoRa. While the tests

worked fine encryption, authentication as well as link optimization needed

manual solutions. Instead of pursuing the pure LoRa approach the switch to

LoRaWAN solved all these and even allowed easily redundant base station setups

plus roaming (e.g. for buoy setups).

Sensor nodes with the custom PCB board and low-cost Heltec Dev Boards were tested for multiple month in the wild and delivered stable measurements. Due to the modular code different combinations of sensors were easy to setup and new sensors added within hours. While writing code for the Davis Anemometer (wind direction and speed) is tested and may be fully supported in later versions of the code.

During the time working on this projects multiple researcher at the University of Hawaii, Manoa (UH) mentioned their interest in low-cost remote setups, using all kinds of sensors which all would be compatible with the Arduino framework. At the same time the Information Technology Services of UH collaborated on improving the coverage of Oahu by deploying multiple high-performance base stations around Honolulu.

While this project could be considered successful as in creating a drop-in replacement for an existing setup and being at the extendible by other, no production deployment is currently running. Due to the COVID-19 pandemic the in-person collaboration with other scientists was lower than hoped for, resulting in a lower variety of real setups around Oahu. Future work and efforts are needed to establish LoRaWAN as the goto solution for wireless metric transportation.

Outlook

Parts of the code should be refactored to allow PIN settings of sensors via the

provision_node.py script rather than the config.h file. This would allow a

single image for all sensors and thereby requiring only Python by the scientists

deploying sensors (in contrast to the current need of Platformio.

Also the assembling of a LoRaWAN tracker should be fully documented. The tracker allows interval or manual tracking of LoRaWAN coverage and can thereby be used by scientists for evaluation of sensor node sites. Before a deployment the tracking device would be taken in-field to verify sufficient coverage of LoRaWAN.

Lastly a custom development board was designed to use the CubeCell Module Plus instead of the development boards, which contain unnecessary parts (like LEDs and buttons) which would not be used in production setups. The custom board is in early development and not yet fully functional.

Code

Code used within this project. It could be used as a base and inspiration for

similar projects. The section consists of a utility section containing Python

code for monitoring and deployment and sensor node, C code which runs on

nodes.

Utility

Monitoring and deployment code written in Python.

mqtt2json.py

# Copyright Paul Spooren <mail@aparcar.org>

#

# SPDX-License-Identifier: GPL-2.0-or-later

import json

from os import getenv

from sys import stderr

import paho.mqtt.client as mqtt

broker = getenv("MQTT_URL", "nam1.cloud.thethings.network")

username = getenv("MQTT_USER", "meshlab@ttn")

token = getenv("MQTT_TOKEN")

assert token is not None, "Please set MQTT_TOKEN env variable"

def on_connect(mqttc, obj, flags, rc):

print("rc: " + str(rc), file=stderr)

def on_message(mqttc, obj, msg):

decoded_message = json.loads(msg.payload.decode("utf-8"))

# use this as node_id to have the unique dev_eui

#node_id = decoded_message["end_device_ids"]["dev_eui"]

# use this as node_id to have the human readable identifier

node_id = msg.topic.split("/")[-2]

if "decoded_payload" in decoded_message.get("uplink_message", {}):

print(

json.dumps(

{

"from": node_id,

"p": decoded_message["uplink_message"]["decoded_payload"],

}

)

)

def on_publish(mqttc, obj, mid):

print("mid: " + str(mid), file=stderr)

def on_subscribe(mqttc, obj, mid, granted_qos):

print("Subscribed: " + str(mid) + " " + str(granted_qos), file=stderr)

def on_log(mqttc, obj, level, string):

print(string)

mqttc = mqtt.Client()

mqttc.username_pw_set(username, token)

mqttc.on_message = on_message

mqttc.on_connect = on_connect

mqttc.on_publish = on_publish

mqttc.on_subscribe = on_subscribe

mqttc.tls_set_context()

# Uncomment to enable debug messages

# mqttc.on_log = on_log

mqttc.connect(broker, 8883, 60)

mqttc.subscribe("#", 0)

mqttc.loop_forever()

provision_node.py

# Copyright Paul Spooren <mail@aparcar.org>

#

# SPDX-License-Identifier: GPL-2.0-or-later

import serial

import sys

import yaml

from pathlib import Path

print(f"{sys.argv[0]} [node_name] [serial_port] [bitrage]")

if len(sys.argv) == 2:

node_name = sys.argv[1]

else:

node_name = "develop"

if len(sys.argv) == 3:

node_serial = sys.argv[2]

else:

node_serial = "/dev/ttyUSB0"

if len(sys.argv) == 4:

node_bitrate = int(sys.argv[3])

else:

node_bitrate = 115200

print(f"Provisioning {node_name} at {node_serial}")

if not Path(node_serial).is_char_device():

print(f"Missing serial connection for node at {node_serial}")

quit(1)

config_path = Path(f"./nodes/{node_name}.yml")

if not config_path.is_file():

print(f"Missing node config at nodes/{node_name}.yml")

quit(1)

config = yaml.safe_load(config_path.read_text())

def AT_command(key, value):

serial_connection.write(bytes("\n", "ascii"))

serial_connection.readline()

at_command = f"AT+{key}={value}"

serial_connection.write(bytes(at_command, "ascii"))

print(at_command)

status = serial_connection.readline().decode("utf-8")

print(f"STATUS: {status}")

if not status.startswith("+OK"):

print(status)

sys.exit(1)

return serial_connection.readline().decode("utf-8")

serial_connection = serial.Serial(node_serial, node_bitrate, timeout=1)

for key, value in config["at_commands"].items():

if not value:

value = "0" * 16

AT_command(key, str(value))

# restart node

AT_command("RESET", 1)

serial_connection.close()

Sensor Node

Code running on sensor node written in C.

main.cpp

// Copyright Paul Spooren <mail@aparcar.org>

//

// SPDX-License-Identifier: GPL-2.0-or-later

#include "Arduino.h".

#include "LoRaWan_APP.h"

#include "MB7389.h"

#include "VH400.h"

#include "config.h"

#include <CayenneLPP.h>

#include <DallasTemperature.h>

#include <OneWire.h>

#include <SPI.h>

#include <Wire.h>

#include <softSerial.h>

#define LoraWan_RGB 0

// This section allows to store data on the device. Specifically this allows to

// store the rain gauge *mm per tip* value.

#define ROW 0

#define ROW_OFFSET 100

// CY_FLASH_SIZEOF_ROW is 256 , CY_SFLASH_USERBASE is 0x0ffff400

#define addr_rain_gauge \

CY_SFLASH_USERBASE + CY_FLASH_SIZEOF_ROW *ROW + ROW_OFFSET

CayenneLPP lpp(LORAWAN_APP_DATA_MAX_SIZE);

// Set to BATTERY_SEND_INTERVAL to send on start

uint32_t battery_send_counter = BATTERY_SEND_INTERVAL;

// Run cycle every minute

uint32_t appTxDutyCycle = 60000;

// Send messages on specific port. For this application all data is transmitted

// on port 2. The port is used to distinguish between packet types, however

// since this implementation uses CayenneLPP which is parsed by the backend, all

// data can be sent over the same port.

uint8_t appPort = 2;

// Initialize variables required for rain gauge use

#ifdef RAIN_GAUGE_PIN

// union to store directly on EEPROM

union {

float number;

uint8_t bytes[4];

} mm_per_tip;

// The tip counter and mm, must reset after each cycle

static volatile uint8_t tips = 0;

static unsigned long last_switch = 0;

#endif

#ifdef DAVIS_SPEED_PIN

static uint32_t rotations = 0;

static unsigned long davis_speed_debounce = 0;

uint32_t davis_speed_send_counter = 0;

#endif

#ifdef DAVIS_DIRECTION_PIN

uint32_t davis_direction_send_counter = 0;

uint32_t davis_direction_total = 0;

#endif

// Initialize variables required for OneWire temperature

//

// The current setup only supports a single connected sensor while it is easily

// possible to monitor multiple OneWire sensors at the same time.

#ifdef ONEWIRE_PIN

OneWire onewire(ONEWIRE_PIN);

DallasTemperature onewire_sensor(&onewire);

uint32_t onewire_send_counter = 0;

float onewire_total = 0.0;

#endif

// Initialize variables required for VH400 moisture sensor

#ifdef VH400_PIN

uint32_t vh400_send_counter = 0;

float vh400_total = 0.0;

#endif

// Initialize variables for MB7389 ultrasonic distance sensor

#ifdef SONIC_RX_PIN

uint32_t sonic_send_counter = 0;

uint32_t sonic_total = 0;

softSerial sonicSerial(0, SONIC_RX_PIN);

#endif

// Prepare the outgoing packet stored in CayenneLPP format

//

// The packet might be empty and sending is omitted for that cycle.

static void prepareTxFrame() {

lpp.reset();

// Send battery status only every "BATTERY_SEND_INTERVAL" minutes

if (battery_send_counter >= BATTERY_SEND_INTERVAL) {

Serial.printf("[%i/%i] Add battery volt\n", battery_send_counter,

BATTERY_SEND_INTERVAL);

// Battery voltage is stored as voltage with ID 1

lpp.addVoltage(1, getBatteryVoltage() / 1000.0);

// Running version is stored as digital output with ID 1

lpp.addDigitalOutput(1, VERSION);

// Reset counter

battery_send_counter = 0;

} else {

Serial.printf("[%i/%i] Skip battery volt\n", battery_send_counter,

BATTERY_SEND_INTERVAL);

battery_send_counter++;

}

#ifdef SONIC_RX_PIN

sonic_total += get_sonic_distance(sonicSerial, 60);

sonic_send_counter++;

if (sonic_send_counter == SONIC_SEND_INTERVAL) {

Serial.printf("[%i/%i] Add sonic\n", sonic_send_counter,

SONIC_SEND_INTERVAL);

// Sea level is stored as distance with ID 1

lpp.addDistance(1, ((float)sonic_total / sonic_send_counter) / 100.0);

// Reset counters

sonic_send_counter = 0;

sonic_total = 0;

} else {

Serial.printf("[%i/%i] Skip sonic\n", sonic_send_counter,

SONIC_SEND_INTERVAL);

}

#endif

#ifdef RAIN_GAUGE_PIN

if (tips > 0) {

Serial.printf("Tips = %i\n", tips);

// Rain fall is stored as analog with ID 1

// The CayenneLPP specification do not support rain fall directly

lpp.addAnalogInput(1, mm_per_tip.number * tips);

// Reset counter

tips = 0;

} else {

Serial.printf("Skip rain gauge\n");

}

#endif

#ifdef DAVIS_SPEED_PIN

davis_speed_send_counter++;

if (davis_speed_send_counter >= DAVIS_SPEED_SEND_INTERVAL) {

Serial.printf("[%i/%i] Add Davis speed\n", davis_speed_send_counter,

DAVIS_SPEED_SEND_INTERVAL);

// Moisture is stored as analog with ID 2

// The CayenneLPP specification do not support moisture directly

lpp.addFrequency(1, rotations / (60 * davis_speed_send_counter));

// Reset counters

davis_speed_send_counter = 0;

rotations = 0;

} else {

Serial.printf("[%i/%i] Skip Davis speed\n", davis_speed_send_counter,

DAVIS_SPEED_SEND_INTERVAL);

}

#endif

#ifdef DAVIS_DIRECTION_PIN

davis_direction_total += analogReadmV(DAVIS_DIRECTION_PIN);

davis_direction_send_counter++;

if (davis_direction_send_counter >= DAVIS_DIRECTION_SEND_INTERVAL) {

Serial.printf("[%i/%i] Add Davis direction\n", davis_direction_send_counter,

DAVIS_DIRECTION_SEND_INTERVAL);

// Moisture is stored as analog with ID 2

// The CayenneLPP specification do not support moisture directly

int direction =

((davis_direction_total / davis_direction_send_counter) / 2400) * 360;

lpp.addDirection(1, direction);

// Reset counters

davis_direction_send_counter = 0;

davis_direction_total = 0;

} else {

Serial.printf("[%i/%i] Skip davis_direction\n",

davis_direction_send_counter, DAVIS_DIRECTION_SEND_INTERVAL);

}

#endif

#ifdef VH400_PIN

vh400_total += read_VH400(VH400_PIN);

vh400_send_counter++;

if (vh400_send_counter >= VH400_SEND_INTERVAL) {

Serial.printf("[%i/%i] Add VH400\n", vh400_send_counter,

VH400_SEND_INTERVAL);

// Moisture is stored as analog with ID 2

// The CayenneLPP specification do not support moisture directly

lpp.addAnalogInput(2, vh400_total / vh400_send_counter);

// Reset counters

vh400_send_counter = 0;

vh400_total = 0.0;

} else {

Serial.printf("[%i/%i] Skip VH400\n", vh400_send_counter,

VH400_SEND_INTERVAL);

}

#endif

#ifdef ONEWIRE_PIN

onewire_sensor.requestTemperatures();

onewire_total += onewire_sensor.getTempCByIndex(0);

onewire_send_counter++;

if (onewire_send_counter >= ONEWIRE_SEND_INTERVAL) {

Serial.printf("[%i/%i] Add OneWire\n", onewire_send_counter,

ONEWIRE_SEND_INTERVAL);

// Temperature is stored as temperature with ID 1

lpp.addTemperature(1, onewire_total / onewire_send_counter);

// Reset counters

onewire_send_counter = 0;

onewire_total = 0.0;

} else {

Serial.printf("[%i/%i] Skip OneWire\n", onewire_send_counter,

ONEWIRE_SEND_INTERVAL);

}

#endif

// Copy CayenneLPP frame to appData, which will be send

lpp.getBuffer(), appDataSize = lpp.getSize();

memcpy(appData, lpp.getBuffer(), appDataSize);

}

// Custom commands to provision device

//

// At this point only the rain gauge command `mmPerTip` is supported, however it

// is easily possible to extend this to e.g. support height setting of the tide

// gauges or other user specific commands.

bool checkUserAt(char *cmd, char *content) {

#ifdef RAIN_GAUGE_PIN

// This command is used to set the tipping bucket size

// - HOBO RG3: 0.254mm/t

// - Misol WH-SP-RG: 0.3851mm/t

if (strcmp(cmd, "mmPerTip") == 0) {

if (atof(content) != mm_per_tip.number) {

mm_per_tip.number = atof(content);

Serial.print("+OK Set mm per tip to ");

Serial.print(mm_per_tip.number, 4);

Serial.println("mm");

Serial.println();

FLASH_update(addr_rain_gauge, mm_per_tip.bytes, sizeof(mm_per_tip.bytes));

} else {

Serial.println("+OK Same mm per tip as before");

}

return true;

}

#endif

return false;

}

#ifdef RAIN_GAUGE_PIN

// Run on each interrupt aka tip of the tipping bucket

void handler_rain_gauge() {

if ((millis() - last_switch) > 15) {

tips++;

last_switch = millis();

}

}

#endif

#ifdef DAVIS_SPEED_PIN

// Run on each interrupt aka tip of the tipping bucket

void handler_davis_speed() {

if ((millis() - davis_speed_debounce) > 15) {

rotations++;

davis_speed_debounce = millis();

}

}

#endif

int get_direction(int davis_voltage) { return (davis_voltage / 2400) * 360; }

// The Arduino setup() function run on every boot

void setup() {

// Set baudrate to 115200

Serial.begin(115200);

Serial.println("So it begins...");

#ifdef RAIN_GAUGE_PIN

// Read mm/t from EEPROM

Serial.println("Enable rain gauge sensor");

FLASH_read_at(addr_rain_gauge, mm_per_tip.bytes, sizeof(mm_per_tip.bytes));

if (mm_per_tip.number == 0.0) {

mm_per_tip.number = DEFAULT_MM_PER_COUNT;

}

Serial.print("Current mm per tip is ");

Serial.print(mm_per_tip.number, 4);

Serial.println("mm");

// Enable interrupt pin for tips

PINMODE_INPUT_PULLUP(RAIN_GAUGE_PIN);

attachInterrupt(RAIN_GAUGE_PIN, handler_rain_gauge, FALLING);

#endif

#ifdef DAVIS_SPEED_PIN

// Read mm/t from EEPROM

Serial.println("Enable Davis speed sensor");

// Enable interrupt pin for tips

PINMODE_INPUT_PULLUP(DAVIS_SPEED_PIN);

attachInterrupt(DAVIS_SPEED_PIN, handler_davis_speed, FALLING);

#endif

#ifdef ONEWIRE_PIN

// Setup OneWire and print single test measurement

Serial.println("Enable OneWire sensor");

onewire_sensor.begin();

onewire_sensor.requestTemperatures();

Serial.print("temperature = ");

Serial.print(onewire_sensor.getTempCByIndex(0), 2);

Serial.println();

#endif

// Enable user input via Serial for AT commands

enableAt();

#ifdef DAVIS_DIRECTION_PIN

// Setup Davis direction sensor and print single test measurement

Serial.println("Enable Davis direction sensor");

pinMode(DAVIS_DIRECTION_PIN, INPUT);

Serial.print("direction = ");

Serial.print(get_direction(analogReadmV(DAVIS_DIRECTION_PIN)));

Serial.println();

#endif

#ifdef VH400_PIN

// Setup VH400 sensor and print single test measurement

Serial.println("Enable VH400 sensor");

pinMode(VH400_PIN, INPUT);

Serial.print("moisture = ");

Serial.print(analogReadmV(VH400_PIN));

// Serial.print(read_VH400(VH400_PIN), 2);

Serial.println();

#endif

#ifdef DAVIS_SPEED_PIN

#endif

#ifdef DAVIS_DIRECTION_PIN

#endif

#ifdef SONIC_RX_PIN

// Print single test measurement

Serial.println("Enable sonic sensor");

Serial.print("distance = ");

Serial.print(get_sonic_distance(sonicSerial, 1));

Serial.println();

#endif

// Set Arduino into the initialization state

deviceState = DEVICE_STATE_INIT;

LoRaWAN.ifskipjoin();

}

void loop() {

switch (deviceState) {

case DEVICE_STATE_INIT: {

getDevParam();

printDevParam();

LoRaWAN.init(loraWanClass, loraWanRegion);

deviceState = DEVICE_STATE_JOIN;

break;

}

case DEVICE_STATE_JOIN: {

LoRaWAN.join();

break;

}

case DEVICE_STATE_SEND: {

prepareTxFrame();

// Do not send empty packages

if (appDataSize > 0) {

LoRaWAN.send();

} else {

Serial.println("Package is empty, don't send anything");

}

deviceState = DEVICE_STATE_CYCLE;

break;

}

case DEVICE_STATE_CYCLE: {

// If sonic sensor is enabled it will measure 60 times a minute and return the

// average. This way waves don't influence tide estimations as much. Since a

// measurement is required every second the duty cycle is skipped and instead

// the get_sonic_distance function runs, which blocks for 60 seconds.

// If no sonic sensor is attached, use the

#ifdef SONIC_RX_PIN

LoRaWAN.sleep();

// Add random delay so sensors don't repetitively send at the same time.

// This is done do avoid a situation where many sensors start at the same

// time and collectively overload the gateway every 60 seconds.

delay(randr(0, APP_TX_DUTYCYCLE_RND));

deviceState = DEVICE_STATE_SEND;

#else

// Same random delay is applied here.

txDutyCycleTime = appTxDutyCycle + randr(0, APP_TX_DUTYCYCLE_RND);

LoRaWAN.cycle(txDutyCycleTime);

deviceState = DEVICE_STATE_SLEEP;

#endif

break;

}

case DEVICE_STATE_SLEEP: {

LoRaWAN.sleep();

break;

}

default: {

deviceState = DEVICE_STATE_INIT;

break;

}

}

}

config.h

/*

* Describes the currently running version. This value is transmitted next to

* the battery voltage and helps to keep track what software version is running

* on nodes. It should be increased whenever a significant change to logic

* happens which may change the behaviour of a running device.

*/

#define VERSION 4

// How often to send battery voltage (and version) in minutes

#define BATTERY_SEND_INTERVAL 360 // 6 hours

// How often to send OneWire temperature in minutes

#define ONEWIRE_SEND_INTERVAL 30

// How often to send MB7389 sonic distance in minutes

#define SONIC_SEND_INTERVAL 10

// How often to send VH400 moisture in minutes

#define VH400_SEND_INTERVAL 3

// How often to send Davis wind speed in minutes

#define DAVIS_SPEED_SEND_INTERVAL 2

// How often to send Davis wind direction in minutes

#define DAVIS_DIRECTION_SEND_INTERVAL 2

/*

* Setting PINs to devices will enable them within the code. The default values

* presented here work fine with Heltec CubeCell boards, allowing to attach all

* sensor at once. However it is also possible to remove any PIN definition and

* thereby disable the sensor completely.

*/

// #define ONEWIRE_PIN GPIO4

//#define SONIC_RX_PIN GPIO1

//#define RAIN_GAUGE_PIN GPIO5

//#define VH400_PIN ADC2

#define DAVIS_SPEED_PIN GPIO5

#define DAVIS_DIRECTION_PIN ADC2

// This defines the fallback value of mm/t if not provided by the node

// configuration file. The default value corresponds to a HOBO RG3.

#define DEFAULT_MM_PER_COUNT 0.254 // 0.01"

/*

* All options below are advanced and specifically for the LoRaWAN library used.

* None of these values should require manual changes except when using outside

* the US915 zone or using ABP rather than OTAA.

*/

// OTAA parameters should be set via AT commands in the configuration file.

uint8_t devEui[] = {0xC0, 0xFF, 0xEE, 0xC0, 0xFF, 0xEE, 0xCA, 0xFE};

uint8_t appEui[] = {0xC0, 0xFF, 0xEE, 0xC0, 0xFF, 0xEE, 0xCA, 0xFE};

uint8_t appKey[] = {0xC0, 0xFF, 0xEE, 0xC0, 0xFF, 0xEE, 0xC0, 0xFF,

0xEE, 0xC0, 0xFF, 0xEE, 0xC0, 0xFF, 0xEE, 0x42};

/*

* While it is possible to use ABP it is not recommended, please use OTAA!

* OTAA is more secure and allows the node and backend to negotiate an ideal

* transmission rate to safe power and air-time.

*/

uint8_t nwkSKey[] = {};

uint8_t appSKey[] = {};

uint32_t devAddr = (uint32_t)0x0;

/*LoraWan channelsmask, default channels 0-7 sub 2*/

uint16_t userChannelsMask[6] = {0xFF00, 0x0000, 0x0000, 0x0000, 0x0000, 0x0000};

/*LoraWan region, select in arduino IDE tools*/

LoRaMacRegion_t loraWanRegion = ACTIVE_REGION;

/*LoraWan Class, Class A and Class C are supported*/

DeviceClass_t loraWanClass = LORAWAN_CLASS;

/*OTAA or ABP*/

bool overTheAirActivation = LORAWAN_NETMODE;

/*ADR enable*/

bool loraWanAdr = LORAWAN_ADR;

/* set LORAWAN_Net_Reserve ON, the node could save the network info to flash,

* when node reset not need to join again */

// bool keepNet = LORAWAN_NET_RESERVE;

bool keepNet = false;

/* Indicates if the node is sending confirmed or unconfirmed messages */

bool isTxConfirmed = false;

/*!

* Number of trials to transmit the frame, if the LoRaMAC layer did not

* receive an acknowledgment. The MAC performs a datarate adaptation,

* according to the LoRaWAN Specification V1.0.2, chapter 18.4, according

* to the following table:

*

* Transmission nb | Data Rate

* ----------------|-----------

* 1 (first) | DR

* 2 | DR

* 3 | max(DR-1,0)

* 4 | max(DR-1,0)

* 5 | max(DR-2,0)

* 6 | max(DR-2,0)

* 7 | max(DR-3,0)

* 8 | max(DR-3,0)

*

* Note, that if NbTrials is set to 1 or 2, the MAC will not decrease

* the datarate, in case the LoRaMAC layer did not receive an acknowledgment

*/

uint8_t confirmedNbTrials = 4;

VH400.cpp

#include "Arduino.h"

float read_VH400(uint8_t VH400_PIN) {

float vh400_voltage = analogReadmV(VH400_PIN) / 1000.0;

float VWC;

// Calculate VWC based on voltages provided by vendor:

// https://vegetronix.com/Products/VH400/VH400-Piecewise-Curve.phtml

if (vh400_voltage <= 1.1) {

VWC = 10 * vh400_voltage - 1;

} else if (vh400_voltage <= 1.3) {

VWC = 25 * vh400_voltage - 17.5;

} else if (vh400_voltage <= 1.82) {

VWC = 48.08 * vh400_voltage - 47.5;

} else if (vh400_voltage <= 2.2) {

VWC = 26.32 * vh400_voltage - 7.89;

} else if (vh400_voltage <= 3.0) {

VWC = 62.5 * vh400_voltage - 87.5;

} else {

VWC = 0.0;

}

return (VWC);

}

MB7389.cpp

#include <softSerial.h>

uint32_t get_sonic_distance(softSerial softwareSerial, uint32_t count) {

boolean foundValue;

boolean foundStart;

String inString;

uint32_t measurements = 0;

uint32_t total = 0;

uint32_t start;

softwareSerial.begin(9600);

while (!softwareSerial.available()) {

}

// Run loop until enough measurements were read

while (measurements < count) {

// Since measurements may fail resulting in a retry after 1/6 seconds, store

// the start time so one a measurement is successfully read, start the next

// measurement exactly a second later.

start = millis();

// Reset variables used to find measurement

foundStart = false;

foundValue = false;

inString = "";

// Flush software serial input

softwareSerial.flush();

// Loop until a single measurement is found

while (!foundValue) {

if (softwareSerial.available()) {

char inChar = softwareSerial.read();

if (foundStart == false) {

// New measurements begin with the character `R`

if (inChar == 'R') {

foundStart = true;

} else {

// If not, skip the letter and repeat

softwareSerial.read();

}

} else {

// Measurements end with character `\r`. If any other value is found

// add it to our measurement.

if (inChar != '\r') {

inString += inChar;

} else {

// If found character is `\r` and therefore end of a measurement,

// check if the length is actually four character. If not, repeat

// the process.

if (inString.length() != 4) {

Serial.println("incomplete measurement");

foundStart = false;

inString = "";

} else {

// Found available measurement, increase counter and begin again

foundValue = true;

total += inString.toInt();

measurements += 1;

// Wait 1 second minus the time it took to read the last

// measurement

delay(1000 - (millis() - start));

}

}

}

} else {

// Give the software serial more time to read characters

delay(50);

}

}

}

// Return average of measurements and convert it to cm (sensor returns mm)

return (total / (count * 10)); // to cm

}

References

[1] Khutsoane, Oratile, Bassey Isong, and Adnan M. Abu-Mahfouz. “IoT devices and applications based on LoRa/LoRaWAN.” IECON 2017-43rd Annual Conference of the IEEE Industrial Electronics Society. IEEE, 2017.

[2] Rizzi, Mattia, et al. “Evaluation of the IoT LoRaWAN solution for distributed measurement applications.” IEEE Transactions on Instrumentation and Measurement 66.12 (2017): 3340-3349.

[3] Davcev, Danco, et al. “IoT agriculture system based on LoRaWAN.” 2018 14th IEEE International Workshop on Factory Communication Systems (WFCS). IEEE, 2018.